As a result of the study, through an integrated approach a descriptive overview of the key components of the innovation management system according to the peculiarities of innovation activities in the mining sector is presented. Based on existing industry analysis reports, it is shown that mining companies need to develop specific innovation capabilities, both internal and external in order to adopt knowledge and devise appropriate innovation-driven growth strategies. The paper is intended to examine core elements of an innovation management system which is aimed at maintaining a company’s innovation practices, improving its innovation performance, increasing innovation capacities and hence expanding the opportunities for future innovation-oriented activities on a continuous basis. These minor producers may require other digital transformation solutions tailored to their capabilities and needs and applicable to their scale of operations. Large-scale mining operations appear to select and apply digital technologies suitable to their needs, whereas operations with lower production rates do not implement the currently available digital technologies to the same extent. Also, an analysis of the actual implementation of digital technologies in 158 active surface and underground mines reveals a limited uptake of digital technologies in general and that the uptake increases with the run-of-mine production. Results demonstrated that currently 107 different digital technologies are pursued in the mining sector.

Relevant technologies were systematically identified using text-mining techniques, and network analyses established the relations between significant technologies. This paper provides an overview of digital technologies currently relevant to mining companies as presented and discussed by mining journals, the media and insight reports of leading consultancy agencies. However, it remains increasingly difficult for mining companies to decide which digital technologies are most relevant to their needs and individual mines. Taking into consideration these key factors and their critical threshold values will help the directors of the participating mine to meet with success in terms of both productivity and OHS in future introduction of innovative equipment projects.ĭigitalisation in mining refers to the use of computerised or digital devices or systems and digitised data that are to reduce costs, improve business productivity, and transform mining practices. Seat quality was identified as a contributor to improving accident rate, while standardisation of the new equipment relative to the old contributed to productivity.

Two factors were found most relevant to all four indicators of performance: the skill requirement and acceptance of the equipment by the operators.

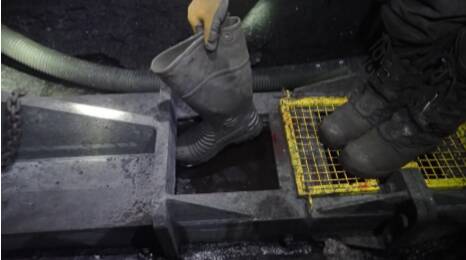

The tool allowed simultaneous identification of the most relevant factors and critical thresholds thereof to establish levels of performance based on four indicators, namely cost per meter drilled, cost per hour of use, availability ratio and accident rate. Ten innovative equipment projects carried out in an underground mine in Quebec were analysed. We used a multi-attribute decision-aid tool, namely the dominance-based rough-set approach. The aim of this study is to identify the key factors that underlie successful introduction of new equipment in underground mines. However, innovative equipment does not by itself ensure success.

Introduction of innovative mining equipment must now meet the double challenge of improving both productivity and OHS. This change in mentality has had an impact on the choice of new equipment introduced underground. With increasing social pressures over the past two decades, mining companies have become more concerned with occupational health and safety (OHS).

0 kommentar(er)

0 kommentar(er)